On January 24 (Lunar New Year's Eve), I celebrated my second daughter's birth. I planned to take a good rest after a busy year and have a good time with my wife and my newborn daughter during the New Year with my paternity leave holidays combined. Unexpectedly, a month of holiday cut down to three days due to the outbreak of COVID-19. On January 27, after taking my wife and daughter out of the hospital, I immediately returned to the workplace. I joined the intense work of ensuring the supply of medical equipment with my colleagues at the Purchasing Department.

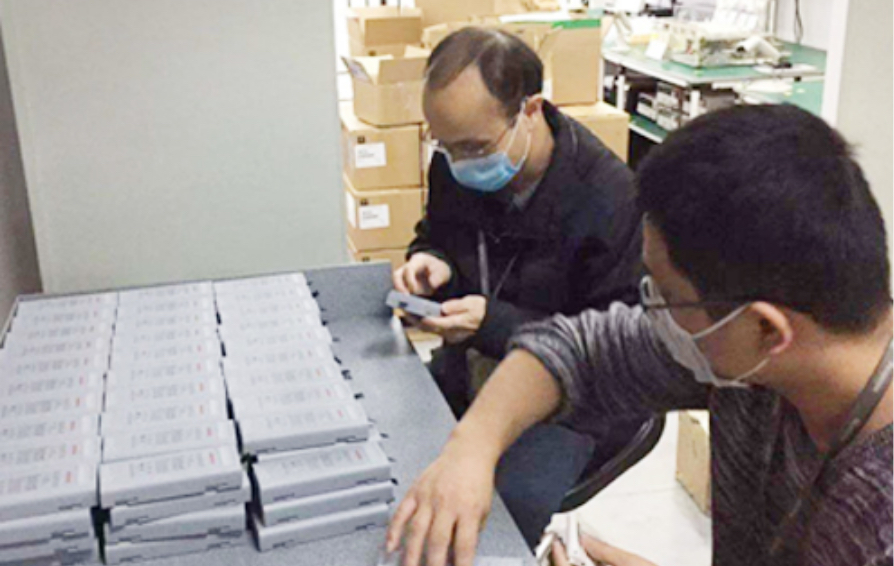

With such a large number of urgent customer needs, the company's stock can only sustain one month's supply. How to ensure the supply of raw materials for the next three months or even longer? That was the challenge to the Purchasing Department. My procurement work mainly included raw materials such as battery cells, motors, radioactive hosts, and sensors. Among them, batteries were essential to all medical equipment, and stable supply must be guaranteed. On January 28, the second day of the resumption of work, I set off for Huizhou, Guangdong, to meet Mindray's key battery supplier Desay. For suppliers, it was a difficult time to resume work. The employees were on holiday, and everything was unpredictable during the time of the epidemic. Fortunately, Desay gave Mindray great support. The workers who had initially been assigned to produce batteries for non-medical products during the Chinese New Year were then manufacturing batteries for Mindray devices, since the production of raw materials for medical device companies was of the highest priority. Desay's battery supply was resolved and I returned to Shenzhen the same day. But what I would face next was supporting the resumption of work of another 30 suppliers.

In my opinion, the challenges the Purchasing Department faced since the end of January could be divided into several phases. The first phase was during the Spring Festival holiday when my team tried to coordinate the resumption of production among the suppliers, yet still couldn't meet the huge demand. The most challenging phase came in March. The supportive stock had been exhausted, but the suppliers were still unable to resume full production capacity. The most acute phase was in April when the Purchasing Department had to search and find alternative suppliers. April was also the time when Mindray Manufacturing reached its peak of production capacity. In May, as COVID-19 cooled down in China, all the suppliers gradually resumed production. The Procurement Department finally got on track and the intensity of the work finally eased. I was relieved.

Time passed so fast that my vacation was delayed by nearly four months. In those four months, my work filled almost all my time except sleep. My wife and daughter had fallen asleep as I went back home late at night, and they had not yet got up as I went to work early in the morning. However, I was already very content to see my family's faces every day, since I knew that many of my colleagues who supported the specialty hospitals weren't able to go home for months. My wife was very supportive of my work. And now, I could finally take my paternity leave, go back home and accompany my wife and children.