What do you think of medical equipment manufacturing?

Do robots occupy the jobs of humans?

Are there endless transport belts in the workshop?

Nowadays, as efficiency becomes an important standard of production intelligence, Mindray cares even more about using intelligence to ensure the safety and accuracy of its products. Here are 7 things we persist in regarding manufacturing.

1. Global Delivery

Meet Multinational Laws and Regulations

With a total area of over 300,000 square meters manufacturing centers in Shenzhen and Nanjing, Mindray is dedicated to lean manufacturing featuring multi-variety and small batch production. Relying on this production mode, it meets diversified needs and comply with the laws of multinational markets, while providing high-quality products to the world. Nearly 80 devices entered two thirds of medical institutions across the United States, which proves the reliability of Mindray manufacturing centers.

2. Intelligent Visualization

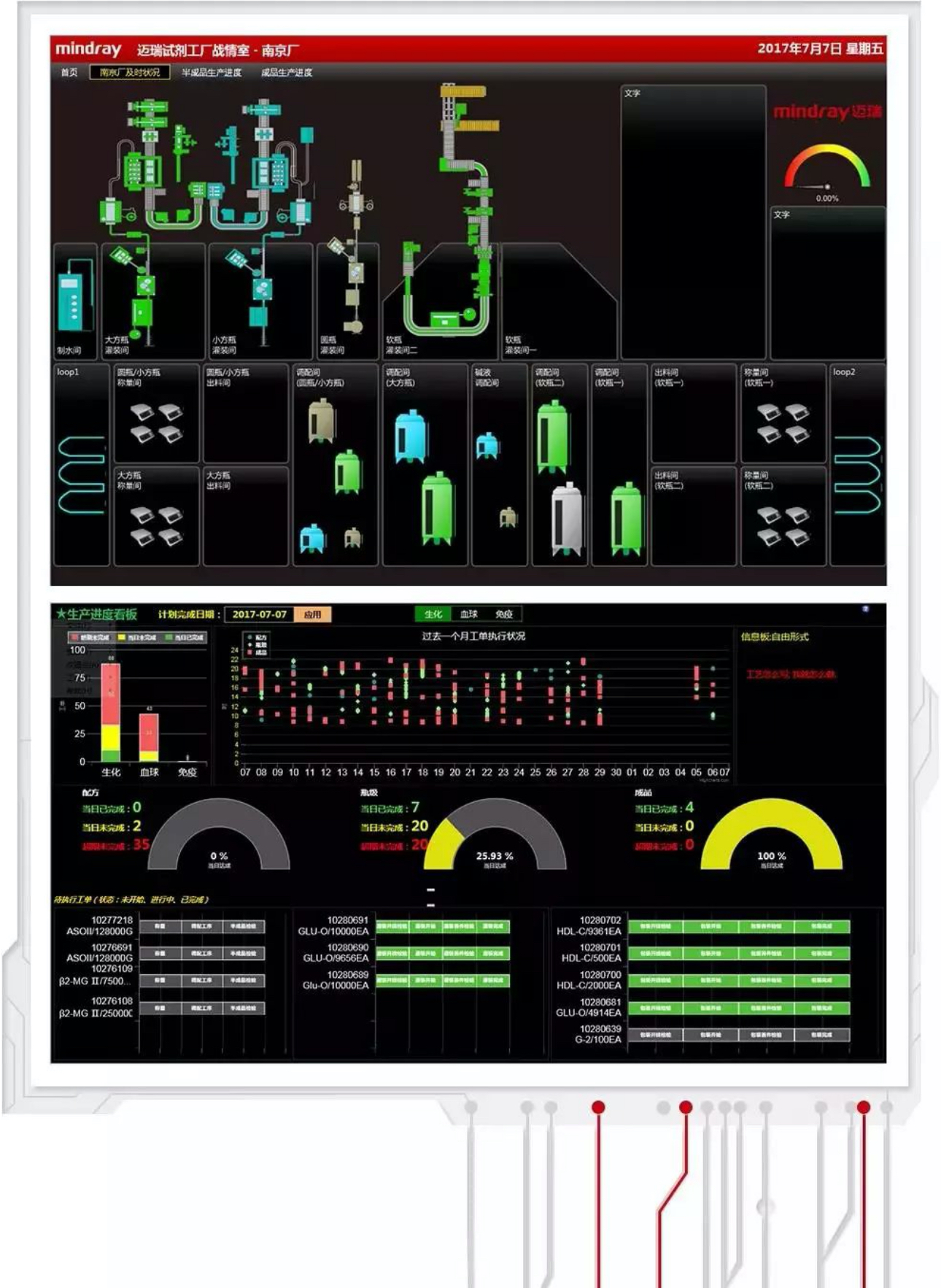

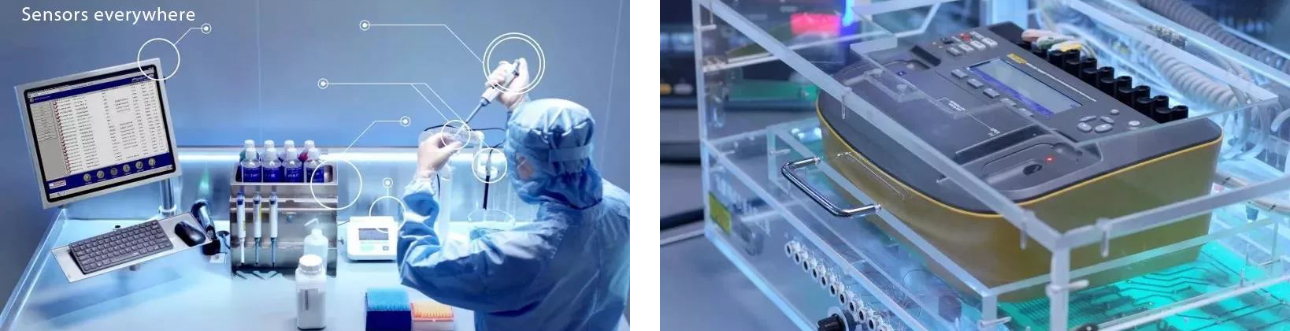

Acquired in Microseconds, Visible in Real Time

Based on fully applied sensing and data transmission technology, Mindray has realized real-time analysis and optimization of production variables with microsecond resolution, which ensure consistency of production procedures. The intelligent collection of data guarantees traceability with a high degree of detail, enabling high-precision and high-safety products to be delivered consistently to global customers.

3. Intelligent Toolings

Calling the Shot in Every Situation

There is no manufacturing without tools. It is clear that Mindray knows it well because it has developed more than 6,200 intelligent tools based on core production technologies and its engineering wisdom. Taking the Intelligent Visible Production Management System as an example, Internet of Things technology is first used to combine the “man, machine, material, methods and environment”. Through setting up process steps, managing personnel permissions, uploading equipment data automatically, scanning materials and identifying the tool’s position, the closed-loop process control of reagent production is ensured in every detail. Moreover, this process mode is used to guarantee the accuracy and efficiency of positioning in complex space.

4. High Precision Machining

Excellence in Both Quality and Quantity

When it comes to “spirit of craftsman”, Mindray's precision machining factory with high precision and digital equipment counts as one. It combines the excellent engineering and systematic design capability, which contribute to the higher production efficiency and quality through a vertically integrated production mode.

5. Sringent Testing

Withstand all difficulties, Always well prepared

True blue will never stain and qualified product fears no test. Mindray is equipped with advanced R&D testing platforms -- the Reliability Testing Laboratory and Standardized Laboratory. In these laboratories, all-round rigorous tests such as high/low temperature, drop, rain, vibration, surge and impact are conducted to assure the reliability and safety of the products in actual clinical use while under different environments.

6. Quality System for All

Strict Material Management Standard to Drive Value of Upstream Supply Chain

In terms of controlling the source of materials, Mindray actively assists in management, overseeing the raw material suppliers and processing technology. Moreover, it re-engraves the incoming material inspection of the design verification scheme carried out in the research and development stage to guarantee the validity and consistency of material certification.

7. Intelligent Warehouse Logistics

In the Right Place at Right Time

Delivering the qualified products to customers on time is crucial. Through intelligent dispatching, warehouse management optimization and constant temperature logistics, Mindray guarantees that the devices are delivered to customers safely and reliably. In-vitro diagnostic reagents serve as an excellent example, which are very sensitive to temperature changes due to their own particularity. It took the lead in establishing a nationwide cold chain transportation system for in-vitro diagnostic reagents, which achieves temperature control, real-time monitoring, and timely warning of temperature breaches by equipping with an efficient emergency plan system.

For medical device manufacturing, it is more important to ensure high quality by intelligent means instead of simply focusing on improving efficiency. This is the unique feature of medical device manufacturing and what matters most to Mindray.