The initial outbreak of COVID-19 in China coincided with the Chinese Lunar New Year. For many healthcare professionals, the 2020 Spring Festival was unforgettable for all the wrong reasons. At the production frontline of critical medical equipment, the employees of Mindray Manufacturing Center saw their workload doubled in an effort to save lives. They found themselves engaged in coordinating anti-pandemic resources, adjusting their processes and overcoming formidable production hurdles, remaining steadfast in combating the pandemic. The production, installation and delivery of medical equipment were completed at a typical Chinese speed and full support was timely rendered to frontline hospitals in their construction and treatment tasks, both of which pooled the painstaking effort of each member at Mindray. Their stories in response to the pandemic shone through this challenging period.

Xu Wenqing

Order Fulfillment Department

I have worked for Mindray Manufacturing Center for years. As soon as I was appointed as the manufacturing site coordinator on the second day of the Lunar New Year, I immediately threw myself at the demanding and urgent workload. In order to speed up the production process, I had to undertake multiple tasks, such as upstream and downstream materials coordination, continuous materials supply and timely storage and transportation of finished products. More importantly, I needed to ensure the logistical support for and the health and safety of our employees. These tasks were highly interconnected and demanding. Thanks to the unrelenting efforts of our entire department, we overcame multiple limitations and fulfilled delivery contracts.

Wei Zhihao

Procurement Engineer

On 2020 Lunar New Year's Eve, I celebrated my daughter's birth. Due to the outbreak of COVID-19, I cut a month's holiday down to three days as I was responsible for the supply of medical equipment. After bringing my wife and daughter home from hospital, I immediately returned to work. The 30-plus suppliers I was in contact with also faced insufficient staff and resources, production capacity and inventory during the pandemic. Over the next four months, I continued to work at high intensity to promptly coordinate with them and look for new supply channels as well, to ensure the procurement for the production team. The daily routine of going out early and returning home late prevented me from spending more time with my family. Thanks to my wife's understanding and selflessness, our small family was able to help many other families suffered in the pandemic.

Xiao Xiaojun

Production Management Department

I was the site manager for equipment production during the pandemic and the biggest challenge I faced was the shortage of production staff. From the start, attendance was less than 60% while the demand for production was over 120%. All members of the Manufacturing Center were seconded to the production line to help, while other departments such as R&D, marketing, and administration took turns to support us. All our colleagues came to the production site and put on worker garments to work together for the same goal. We tried our utmost to keep the production line running around the clock to ensure we met all our deliveries. A strong sense of cohesiveness was felt by everyone at Mindray.

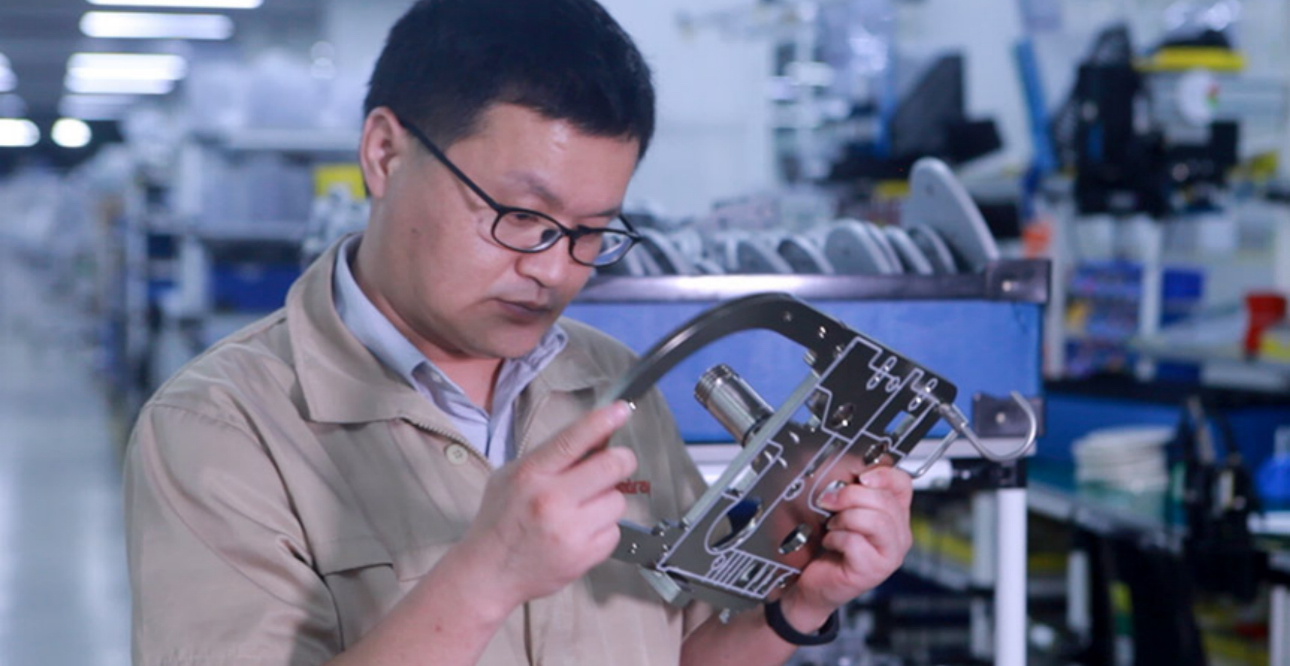

Huang Zhengwei

Anesthesia and Ventilator Production Department

Ventilators are important strategic medical equipment in the fight against the pandemic, so every additional ventilator produced means that more lives can be saved. Keenly aware of the importance of my work, I gave up my vacation to return to work early before the Lunar New Year. After solving the priority of staff shortage, we also got actively involved in adjusting the production process. I couldn't not tell you how many days we worked late into the night and even all night. What I could tell you was that, two months later, we were actually producing four times the number of ventilators compared with the same period last year, sending hope of relief to numerous major hospitals nationwide.

Wang Tao

Warehouse Management Department

Hardly had I been working at Mindray for one month when I was appointed as the coordinator for equipment shipping, part of the whole production task to fight pandemic. I worked with the team for three consecutive days right before Chinese New Year, and had a special dinner at my workstation on New Year's Eve to ensure a smooth delivery of our products. This experience has given me a real sense of the importance of my work at Mindray.

Nearly 2,000 workers resumed work during the Chinese New Year holiday.

200 service engineers and nearly 1,000 R&D engineers rushed to the rescue.

Production capacity for both monitors and ventilators increased by 3-4 times.

To ensure the timely delivery of medical equipment needed at the frontline, Mindray's Manufacturing Center resumed production on the second day of the first lunar month of 2020. Workers volunteered to work overtime and made shifts every 12 hours. Due to the pandemic and the Spring Festival holiday, only less than half of the workers returned to work. To fill the gap, R&D and service engineers rushed to the rescue and supported the front-liners with their expertise.